- Carbon Fiber Telescopic Antenna Mast

- Carbon Fiber Non-Rotating Telescopic Pole

- CARBON FIBER AIR DUCATI

- CARBON FIBER AUTO PARTS

- CARBON FIBER BMW PARTS

- CARBON FIBER BODY PANELS

- CARBON FIBER AUTO ACCESSORIES

- CARBON FIBER CAR PARTS

- CARBON FIBER COLD AIR INTAKE PIPE

- CARBON FIBER Robotic Arm DRONE PARTS

- Customize CARBON FIBER MOTORCYCLE PARTS

- CARBON FIBER AUTO INTAKE TUBES

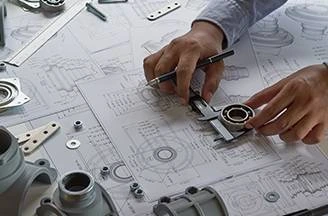

- CUSTOM CARBON FIBER CAR PARTS

- CUSTOMIZE DRONE BODY PARTS

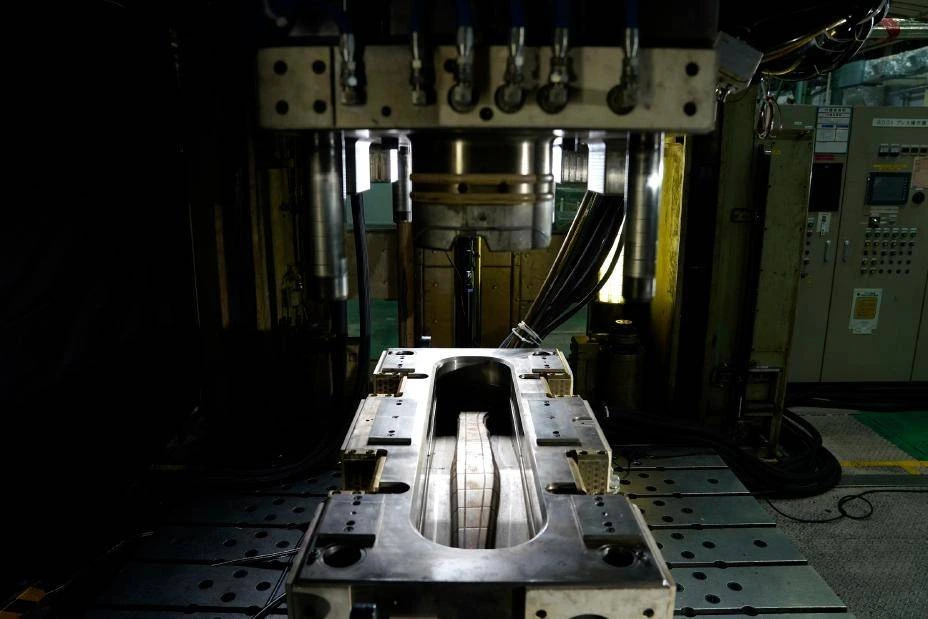

- MAKING CARBON FIBER PARTS

- PORSCHE CARBON FIBER PARTS

- CARBON FIBER TELESCOPIC AERIAL PHOTOGRAPHY POLE

- CARBON FIBER TELESCOPIC CAMERA POLE

- CARBON FIBER TELESCOPIC INSPECTION POLE

- TRIPOD FOR SPORTS VIDEO

- ENDZONE CAMERA SYSTEM

- EXTENDABLE TELESCOPIC POLE

- HEAVY DUTY TELESCOPING EXTENSION POLE

- TELESCOPIC VIDEO CAMERA SYSTEM

- CARBON FIBER AXLE SHAFTS

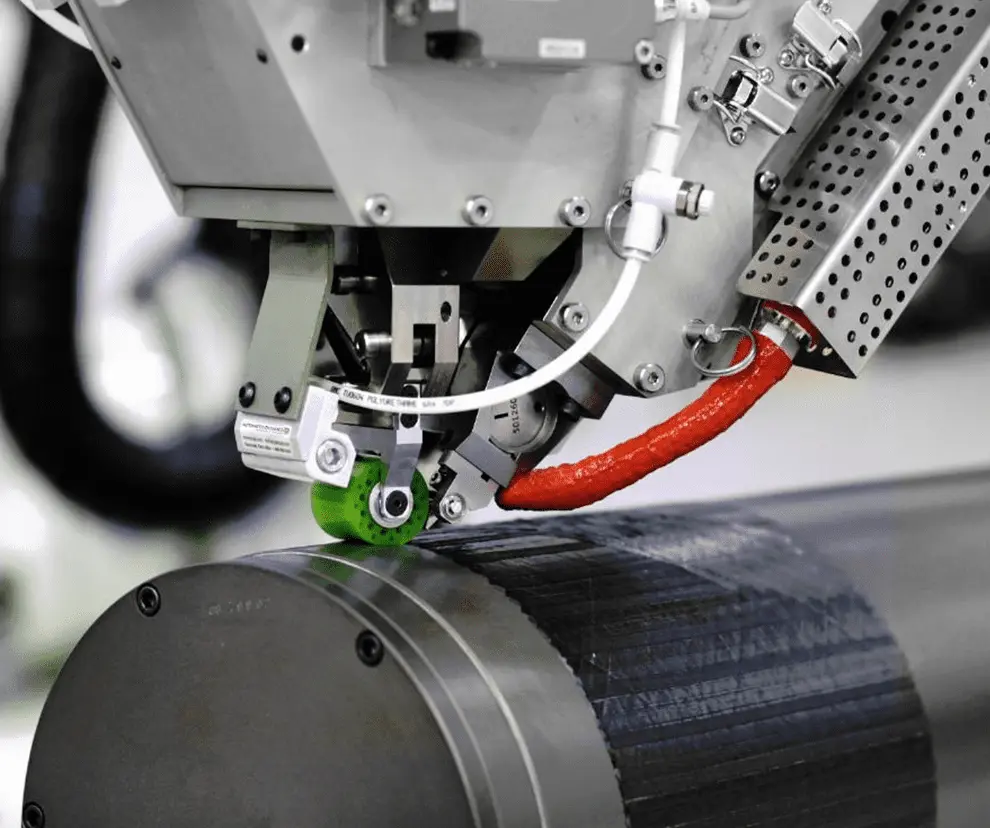

- CARBON FIBER MACHINERY ROLLER

- CARBON FIBER ROLLERS

- CARBON FIBER HEXAGONAL TUBE

- CARBON FIBER KEVLAR TUBING

- CARBON FIBER OCTAGONAL TUBE

- OVAL CARBON FIBER TUBE

- CARBON FIBER RECTANGULAR TUBE

- CARBON FIBER ROUND TUBE

- CARBON FIBER SQUARE TUBE

- CARBON FIBER FILAMENT WINDING TUBE

- PULTRUDED CARBON FIBER RODS TUBES

- ROLL-WRAPPED CARBON FIBER TUBE

- TAPERED CARBON FIBER TUBE