Room 1002, Brilliance Building, Nihonbashihamacho Park, 2-57-1 Nihonbashihamacho, Chuo-ku, Tokyo, Japan

Email: sales@tiptopcomposites.com

Request A Quote

Please let us know your requirements and we will get back to you with a quote.

We can mold carbon fiber composite material to almost any automobile accessory. The main upsides are its strength, light weight and appearance. Most carbon fiber auto parts are only painted with clear coat to preserve the unique 3D vision of the carbon fiber weaves.

In the fast-developing automotive industry, carbon fiber finds its place in the design of the special interior and exterior components, such as hoods, cooling system, tail fins, etc.

Tiptop composites offers the complete service for automobile parts , from the beginning of mold design, material and manufacture process choice , fiber layup , curing , coating and holes machining.

We own a professional team, who works on auto industries for more than 12 years. We offer optional manufacturing process, such as hand-lay up, mold compression, vacuum bag or autoclave.

Carbon fiber auto parts’ main advantages are as following:

ALL SHAPED PARTS ARE EXAMPLES OF COOPERATION CASES BETWEEN US AND OUR CUSTOMERS. THEY ARE JUST FOR DISPLAY, NOT FOR SALE. PLEASE CONTACT US TO CUSTOM YOUR PARTS.

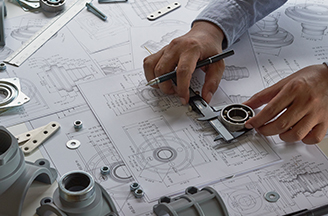

Our design teams are experts in composite materials and manufacturing, turning your ideas into

reality, from complex large programs to smaller component projects. We have practical

engineering skills and extensive experience of composites in product development and production

for a diverse range of applications that will ensure your project is in the right way, saving

time and costs. If you have a question, please call us or request a quote.

Rapid prototypes of composite products are helpful for optimizing specifications, and processes

& lower risk. We are good at the rapid production of cost-effective, proof-of-concept

models. Our knowledge of and expertise with composite products and materials play a huge role in

helping our clients achieve success. If you have a question, please call us or request a quote.

TIPTOP Composites team has extensive experience in composites tooling design and engineering. We

can produce the right tool for your needs ranging from prototype to full production tooling for

long-run production. Multiple tooling materials include fiberglass, silicon, aluminum, and

steel. If you have a question, please call us or request a quote.

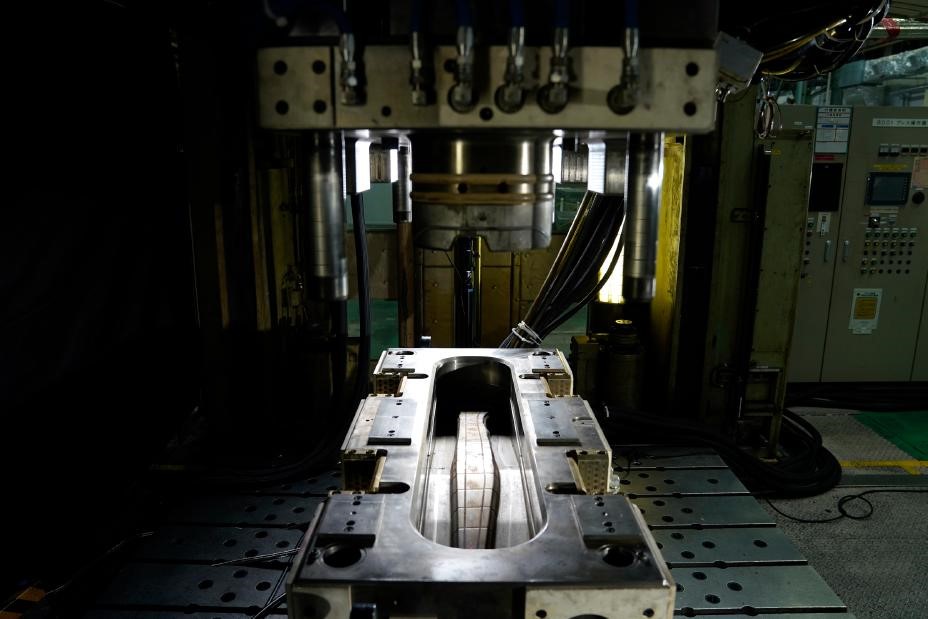

With the advanced processes of roll-wrapping, filament winding, autoclave, compression molding,

and pultrusion, our facilities are set up to provide a steady, consistent, reliable production

run of composite products. Handling both small and large production runs for customers including

the manufacture of OEM parts, plates, round and shaped tubing, and composites telescopic pole

systems. QC is a huge priority to us, ensuring our products are of the highest standard. If you

have a question, please call us or request a quote.

We manufacture high-end carbon fiber composite products, and we are experienced in machining

them, many of our services are available below, if you need any of them, please call us or

request a quote.

We have excellent experience in painting carbon fiber products to suit your needs, especially

special requirements of chemical and high temperature resistance if you have a question, please

call us or request a quote.

TIPTOP Composites has professional experience and bonding assemblies of carbon fiber composites

and provide the bonding and assembly process for your projects, save your team labor cost and

time. If you need them, please call us or request a quote.

We have guarantee period for our products. No matter you want to change the design, adjust the

parameters or there is quality problem, we can manufacture according to your design and idea. We

are always there.

Room 1002, Brilliance Building, Nihonbashihamacho Park, 2-57-1 Nihonbashihamacho, Chuo-ku, Tokyo, Japan

Email: sales@tiptopcomposites.com

Please let us know your requirements and we will get back to you with a quote.